Kammerrakel - Entwicklung eines innovativen Kammerrakelsystems für Tiefdruckmaschinen

Die zunehmende Substitution von Druckmedien durch das Internet sowie Auswirkungen der demografischen Entwicklung auf das Kauf- und Leseverhalten der Bevölkerung haben in den letzten Jahren zu einem Rückgang des Druckaufkommens und einer starken Reduzierung der Arbeitsplätze in der Druckindustrie („Strukturkrise“) geführt. Diese Entwicklung hat sich zwar in jüngster Zeit etwas entspannt, dennoch sind Nachrichten über Insolvenzen und Standortschließungen von Druckereien weiterhin an der Tagesordnung.

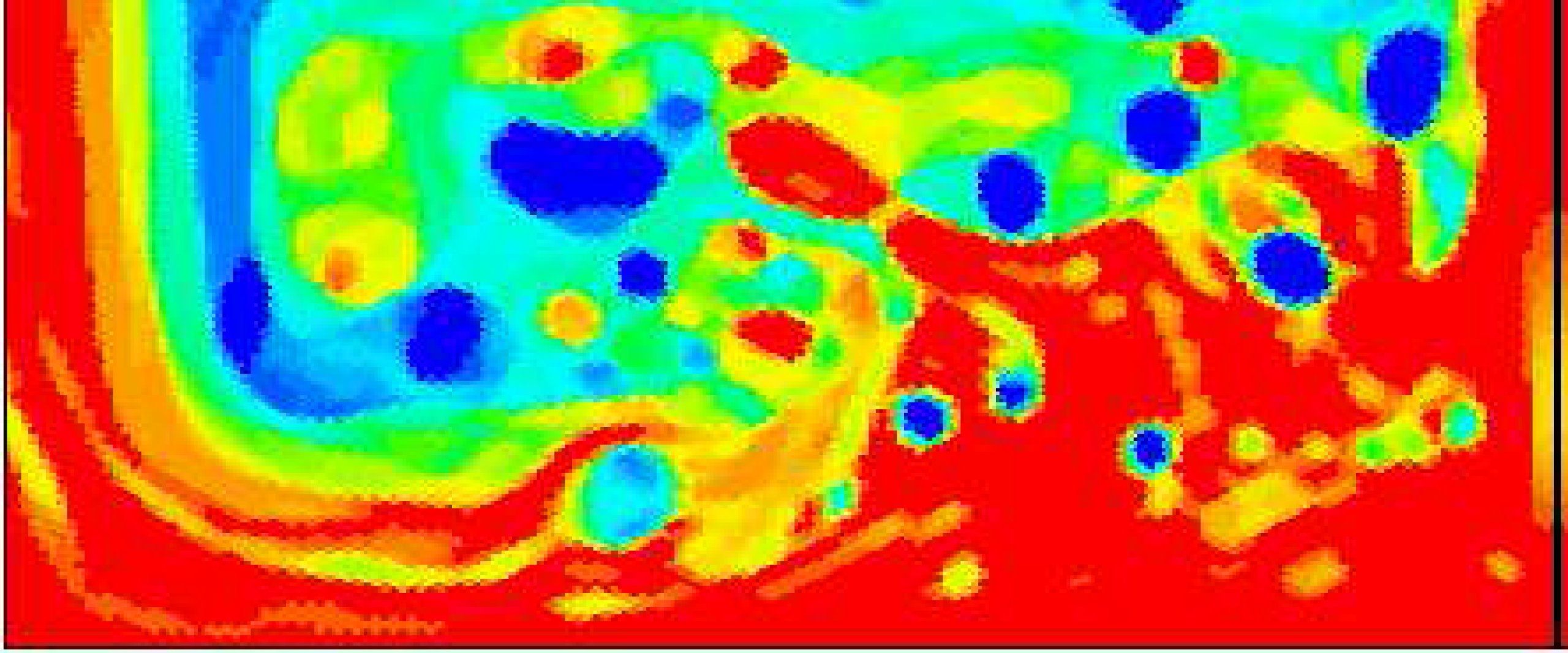

Im Tiefdruck werden bislang Rakel zum Abstreifen von Farbe eingesetzt. Kammerrakelsysteme kommen beispielsweise im Flexodruck-Bereich oder im Wasserlosen Offsetdruck zum Einsatz. Im Flexodruck herrschen durch seine homogene Näpfchenverteilung und dem immer gleichen Durchmesser der Druckform definierte Verhältnisse. Die beiden Komponenten Rasterwalze und Kammerrakel sind somit meist optimal aufeinander abgestimmt. Im Gegensatz zum Flexodruck bestehen im Tiefdruck keine homogenen und damit definierten Verhältnisse, da die Tiefdruckzylinder (= Formzylinder) je nach Druckbild mit einer Rasterung (Näpfchen) versehen sind. Größe und Muster der Näpfchen geben das erforderliche Druckbild wieder.

Ziel des Projektes ist es ein geschlossenes Kammerrakelsystem für den Tiefdruck zu entwickeln, mit welchem im Vergleich zum aktuellen Stand der Technik erstmalig die Vorteile von Kammerrakeln auf den Tiefdruckbereich übertragen werden.